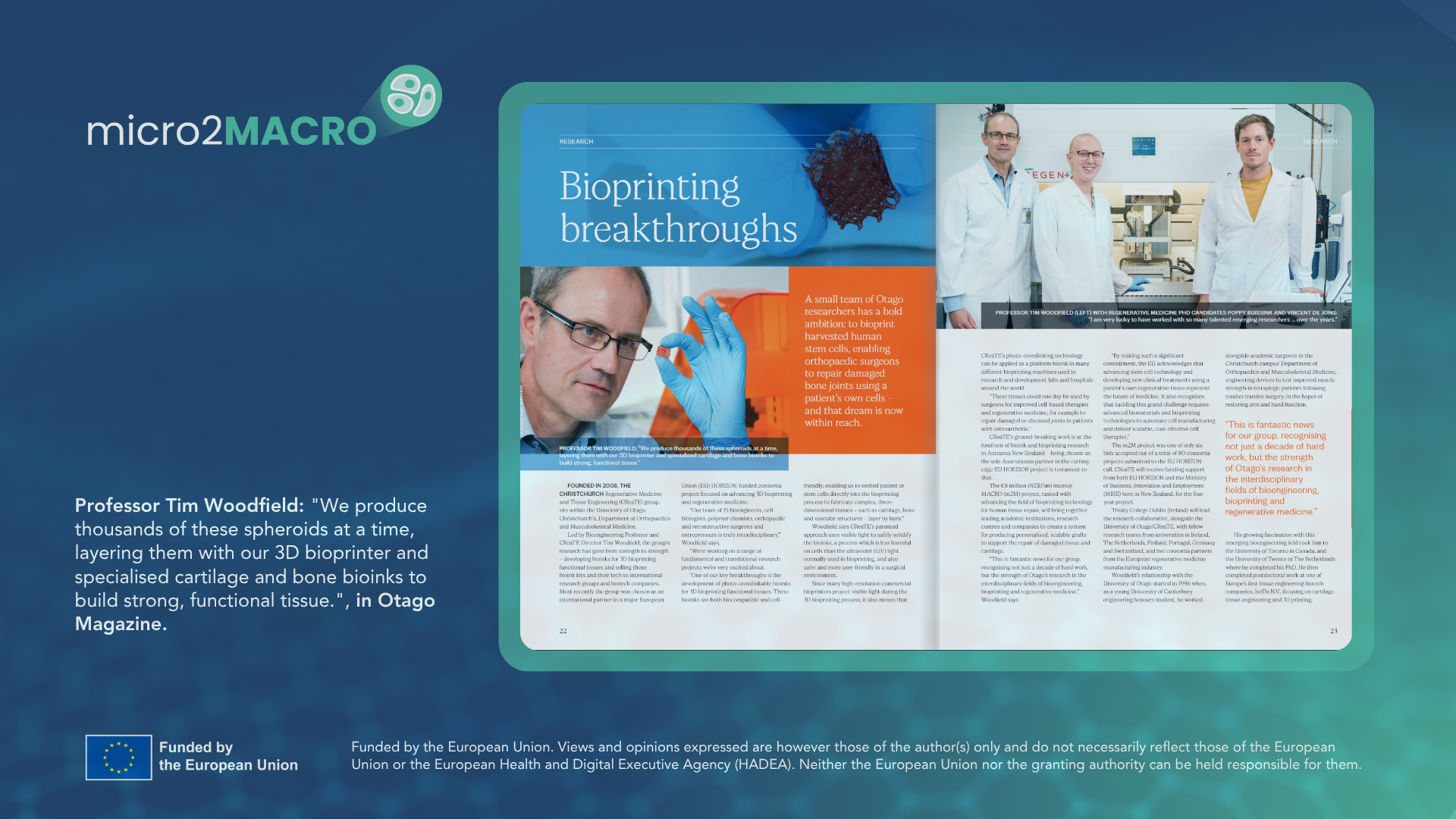

Our partners from the University of Otago recently discussed their work, including insights into m2M, in the latest issue of the Otago Magazine. Led by Professor Tim Woodfield, a team of dedicated scientists are applying advanced technology to create strong, functional tissue for repairing damaged bone joints.

At the core of their innovative approach is the production of thousands of microscopic spheroids. These cellular building blocks are then meticulously layered using a sophisticated 3D bioprinter. The process is further enhanced by the application of specialised cartilage and bone bioinks, acting as a scaffold and nutrient-rich environment to guide tissue formation.

“We produce thousands of these spheroids at a time, layering them with our 3D bioprinter and specialised cartilage and bone bioinks to build strong, functional tissue,” explains Professor Woodfield. This intricate method aims to replicate the complex structures of native tissue, offering a promising solution for patients suffering from joint degeneration and injuries.

The research holds immense potential for advancing therapies that can regenerate damaged bone and cartilage, moving closer to a future where functional biological replacements can be custom-made for individuals in need.

Discover the full article here (page 22-24).